|

|

HYDRAULIC PRESS CLOSED FRAME

Heavy duty welded "H" frame construction

Minimal deflection

Extended tool life

Narrow design

High quality hidraulic group

Tables in rectified and stabilized steel

"T" slots for accurate tools fixing

Easy maintenance

Cushion stroke (optional)

Variety of operations (forming, blanking, straightening, etc)

|

23.11.2016

|

|

|

HYDRAULIC PRESS FOUR COLUMNS

4 columns construction

All sides tooling access

Great quality/price ratio

Narrow design

High quality hidraulic group

Tables in rectified and stabilized steel

"T" slots for accurate tools fixing

Easy maintenance

Cushion stroke (optional)

Variety of operations (forming, blanking, straightening, etc)

|

23.11.2016

|

|

|

HYDRAULIC PRESS C FRAME

Heavy duty welded "C" frame construction

Minimal deflection

Extended tool life

Narrow design

High quality hidraulic group

Tables in rectified and stabilized steel

"T" slots for accurate tools fixing

Easy maintenance

Cushion stroke (optional)

Variety of operations (forming, blanking, straightening, etc)

|

23.11.2016

|

|

|

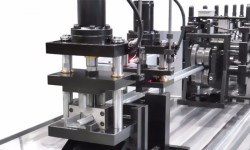

ROLL FORMING LINES

ROLL FORMING LINES

|

23.11.2016

|

|

|

TUBE END FORMING MACHINES

Our end forming machines can manipulate up to 150mm OD tube and cover a wide range of diameters and applications. With one to three station end forming machines, along with the ability to integrate additional punching stations, AMOB can cater for any application with our in-house custom design and manufacturing abilities. With a small compact operating area, these machines can be easily integrated within an automatic production cell. These fully hydraulic machines enable consistency, reliability and fast production cycle times, and can be easily attached to a wide range of systems.

|

23.11.2016

|

|

|

SECTION BENDING ROLLS

The MAH-AC range of section bending machines caters for high end, heavy-duty profile and section bending.

Capable of bending up to IPE 1000 beam, they are the largest roll benders in the world in terms of capacity and size. Like all machines from the MAH-AC range, these are the first products from AMOB to feature planetary moving bottom rolls - allowing for faster and tighter bending and a more efficient production time. This range is available in both CNC and NC with AMOB’s specially developed auto learning software, which removes the need to do sacrificial test bends and therefore reduces scrap material and wasted production time.

|

23.11.2016

|

|

|

ANGLE BENDING ROLLS

The MAH-AC series carries the largest capacity profile bending machines in the world. With planetary moving bottom rolls, they can achieve faster, tighter bending with fewer passes, which results in reduced cycle times. This range is available in both CNC and NC with AMOB’s specially developed auto learning software, which removes the need to do sacrificial test bends and therefore reduces scrap material and wasted production time.

If bending the largest profiles is a requirement then look no further than the MAH-AC series from AMOB.

|

23.11.2016

|

|

|

CNC PROFILE BENDERS

The MAH-CNC range from AMOB provides outstanding production cycle times, un-matched reliability and the production of products not possible on lower level machines. These are the first machines in AMOB’s profile section range that are fully computer-controlled. This technology allows for producing elliptical shapes on a large scale with unbeatable repeatability - plus, the MAH-CNC range is able to put multiple radiuses into a single profile using both progressive and direct pressure, opening up a new sector for product manufacture. The user-friendly 2D CNC controls make this series a popular choice for profile bending sub-contractors and aluminium window and door producers, along with greenhouse manufacturers and other similar industries.

The MAH CNC series takes profile bending to the next level and allows the production of products that is just not possible on MAH and MAM series machines.

|

23.11.2016

|

|

|

HYDRAULIC PROFILE BENDERS

AMOB’s MAH series of hydraulic top roll profile bending machines are the backbone of the biggest selection of roll benders in the world. Extremely user-friendly, again they are completely accessible for apprentices and experienced operatives alike. The top roll position is displayed on the DRO, based within the free standing operator control unit. The MAH series is perfect for those applications that require multiple passes, where repeatability is key. Available in two and three driven roll these machines can cater for the largest range of profiles in the market place. The three driven roll machines suit tighter radiuses and minimise material marking. Both horizontal and vertical working positions ensure that even in the smallest work spaces an MAH series profile bender will have its place. The MAH series is a perfect compromise between capacity, repeatability, ease of use and reduction in production cycle times.

|

23.11.2016

|

|

|

MANUAL PROFILE BENDERS

AMOB’s MAM series of manual top roll profile bending machines are an entry level to the biggest range of section benders in the world. They are extremely user-friendly and the most economical way of roll bending a wide variety of different profiles. The top roll position is manually adjusted with a linear scale for repeatability. There are also locking nuts to secure the top roll position to ensure repeatability in single pass production runs. The MAM series features both two and three driven rolls to suit every application - the three driven roll machines suit tighter radiuses and minimise material marking. The MAM series’ simplicity and reliability ensures that anyone from apprentices through to experienced workers will easily maximise the capabilities of these machines. Both horizontal and vertical working positions ensure that even in the smallest work spaces an MAM series profile bender will have its place.

The MAM series is a great, cost-effective way to get into the profile bending market.

|

23.11.2016

|

|

|

TUBE BENDERS

AMOB’s mandrel-less tube & pipe bending machines cover the needs of those bending 3D centre line radiuses and above. Typically with a thick wall, these tubes do not require a mandrel which promotes quick tooling changeover and reduced setup time. With great portability and a small footprint these machines can be moved and stored as and when required, and with a numerically controlled stop system they promote both reliability and repeatability. Due to the user interface these machines can be used by both the most seasoned operator and a newly appointed apprentice. If large radius, thick walled tube bending is your business then AMOB has your solution.

|

23.11.2016

|

|

|

NC BOILER TUBE BENDERS

When 1D CLR bending is required or minimal wall thinning is critical, AMOB provides the most efficient and innovative solution for producing extra tight radius bends with minimal deformation. With a capacity of up to 320mm, the booster device from AMOB puts us at the forefront of the market in terms of elongation and deformation percentages - which are so key in this market sector.

The booster device, used in conjunction with a fully hydraulic numerically controlled machine, ensures compliant bends time after time. With the ability to combine both state-of-the-art machinery innovation with proven tooling design and production techniques, AMOB is at the forefront of the boiler production sector.

|

23.11.2016

|

|

|

NC PIPE BENDERS

Our CH series is the backbone of our tube and profile bending machines. Their rigidity, stability and untouchable precision in exceptional conditions such as humidity or harsh temperatures is what makes them stand out from the crowd.

Ranging from 10mm up to 420mm OD these machines are suited for use in a wide range of pipe manufacturing sectors and industries. Available in NC1 and NC2. There’s also the option to add welding detection, punching/cutting mechanisms and integrated loading and unloading systems if necessary.

These multi-faceted models are easy to operate and suitable for almost all types of applications and industries.

|

23.11.2016

|

|

|

ELECTRIC CNC TUBE BENDING MACHINES

AMOB electric CNC tube bending machines Ce CNC R series are the ultimate in efficiency and green technology. This innovative range of products was born out of a growing concern with rising energy prices and production costs, and a need to reduce energy consumption intelligently.

Processing tube from 10mm up to 90mm OD, these machines are ideal for medium to large jobs. Available in single stack, double stack or multi-stack capabilities as well as fixed and variable radiuses in the same cycle, they also allow bends with no straight between them when equipped with more than one stack feature. There is also the option to add welding detection, punching/cutting mechanisms and integrated loading or unloading systems, and all Ce CNC R series machines are equipped with the latest AMOB 3D bending software. If you’re looking for something in between the CH and e-MOB series, these hybrids are a great compromise.

|

23.11.2016

|

|

|

FULLY ELECTRIC CNC TUBE BENDERS

The AMOB all-electric CNC eMOB series features state-of-the-art bending technology. Processing tube from 10mm up to 150mm OD, these machines have multi-stack capability. They can bend fixed and variable radiuses within the same cycle and allow bending with no straight between them. A carriage booster allows bends with radiuses as tight as 1D and eliminates clamping marks. Welding detection, punching/cutting mechanisms and integrated loading/unloading systems are also available.

eMOB series machines are all equipped with the newly updated user-friendly AMOB 3D SOFTWARE. Amongst other features it allows automatic spring-back compensation as well as correction “in cycle”, stores tooling configuration and positions, runs anti-collision and interpolates all 9 axis. This shortens setting up and cycle times, eliminating waste and testing periods during the tooling changeover process. Ideal for those working with premium materials, where any error is critical.

|

23.11.2016

|