|

|

BEVEL CUTTING SYSTEM

• Compact Design

• The Worlds Lightest Bevel Head

• Full Collision Protection

• Beveling Range From 0 to 45° Deg. (0-60° optional)

• Maximum Rotation Angle 540°

• With One Button Press You Can Change The Cutting From Square to Bevel

• Different weld grooves Y - Groove, V-Groove,Bevel-Square-Bevel,

X - Groove, Different Thicknesses

|

19.11.2016

|

|

|

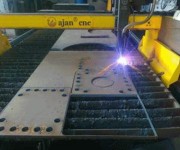

COMBINED CNC PLASMA CUTTING MACHINES

• Ability to cut pipes ranged between 50 and 600mm diameter.

• Steel constructed body.

• Precision Plasma 130 / 260 Amper Generator.

• Marking.

• Automatic Torch Height Control.

• Working with standart DIN/ISO G codes ability.

• Ability of working with DXF and NC toolpath files.

• Resume feature.

• Backward contour positioning.

• Automatic Microjoint.

• Nesting Software package

|

19.11.2016

|

|

|

GRATING CUTTING OXY-FUEL SYSTEM

This system is used for cutting.

•Full Joint Grating

•Press Locked Grating

•Welded Press Fitting Grating

•Forge Welded Grating

These type of grating are used widely in Platforms,Racks,Flooring,Power Plants,Stair Steps.

|

19.11.2016

|

|

|

OXY-FUEL CNC CUTTING MACHINES

Multi head oxy fuel cutting possibility.

• Automatic torch height control.

• Automatic oxy fuel ignition.

• Automatic or manual CNC gas control ( console )

• Quickly switching between Plasma and Oxy mode on the keyboard.

• Nesting Software package

|

19.11.2016

|

|

|

BKM 2500

BKM 2500

Pipe Legth (X Axis) 6000 mm

Pipe Minimum Diametre Ø 1000 mm

Pipe Maximum Diametre Ø 2500 mm

Maximum Pipe Thickness

For 130 Ampere Jenerator 25 mm

For 260 Ampere Jenerator 40 mm

|

19.11.2016

|

|

|

PIPE CNC PLASMA CUTTING MACHINES

AJAN BKM CNC SERIES has been designed for satisfying the requirements of the user’s to be able to cut pipes and sheet metal with CNC plasma cutting system. First of all, the most important differences from the similar machines are that the conventional plasma cutting generator hasn’t been used and it has been equipped with Precision Plasma series 130 Ampere or 260 Ampere precise cutting plasma generator, torch and the required gas selections can be made automatically. For that reason, it can cut steel, chrome and aluminium pipes with high accurancy.

|

19.11.2016

|

|

|

STANDARD CNC PLASMA CUTTING MACHINES

Steel structure

• Dual side rack, pinion system AC Servo motor on X axis, and Y axis.

• Precision Plasma 130/260 Ampere .

• Standard Marking on Precision Plasma

• Automatic torch height control.

• Effective cutting without reducing the cutting speed for the vectors

which have the same start and end angles (High speed machining )

• The ability to go back to any position and resume cutting.

• Resume feature.

• Working with standard DIN/ISO G Codes.

• Possibility of working with DXF,ESSI and NC toolpath files.

• The possibilty to override all the parameters while the machine is working

• Free AJAN Drawing software.

• 15 m/min. rapid traverse speed.

• X axis can be increased on request.

• Optional ventilation system.

• Nesting Software package

|

19.11.2016

|