|

|

175 DIA tool grinding machine

The Agathon 175 DIA tungsten carbide tool grinding machines meet all the requirements for effective precision grinding of turning and boring tools of all types, as used on turret and center lathes.

A large range of accessories further broadens the application range.

|

18.11.2016

|

|

|

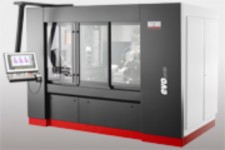

Evo Penta 5-axis grinding center

High-precision 5-axis grinding center for the machining of indexable inserts with complex geometries.

The Evo Penta replaces the well known for its high productivity and flexibility Penta Plus. The extended travel ranges and swivel angle in combination with 5 axes allow the machining of complex workpiece geometries on both sides without re-clamping. Internal and external dressing processes can be freely combined. The Evo Penta is equipped with the proven, easily accessible Penta workpiece spindle head as well as powerful, low-maintenance direct drives on the X, Y and C axes.

The grinding area is separated from the handling area. The handling area of the Evo Penta is equipped with a 4-axis SCARA robot and two trays, whereby e.g. blanks and finished inserts can be separated. The pallet storage system with up to 16 trays ensures maximum production autonomy.

The Evo Penta is characterized by high material removal rates, short grinding times and short idle times. The use of Power Grind enables to reduce the cycle time by up to 50%.

|

18.11.2016

|

|

|

5-axis indexable insert grinding machine PENTA plus

The application of the flexible clamping system also allows the automatic cutting all sides of rear cut grooving inserts with close tolerances. And the extremely short changeover times between clamping systems and clamping holder make the Agathon PENTA plus highly flexible.

The new machine concept guarantees maximum freedom of movement by using 3 rotative and 2 translative axes. Even the most complex indexable insert geometries can be time-saving programmed with the Agathon's software.

The 5-axis indexable insert grinding machine PENTA plus is the fully-automatic grinding center of the very latest generation. As such, it is the solution to the extensive efficiency improvement in the indexable-insert production.

|

18.11.2016

|

|

|

Evo Combi 4-axis peripheral grinding machine

High-precision 4-axis grinding center for the machining of indexable inserts on the periphery and two K-Lands in a single clamping.

The 4-axis peripheral grinding machine Evo Combi differs from its predecessor, the Combi Plus, by enlarged swivel angle and travel ranges as well as more powerful linear motors. The spectrum for the production of workpieces without re-clamping has been significantly expanded.

A new workpiece spindle head with wear-free, faster B-axis is ideal for the processing of round inserts. The Evo Combi is equipped with an improved force measurement system that determines the relevant process forces during grinding and serves the systematic process optimization. As novelty, two trays are located in the workspace of the SCARA robot, whereby e.g. blanks and finished inserts can be separated. The pallet storage system with up to 16 trays ensures high production autonomy.

The Evo Combi is characterized by an easy accessibility, a tidy and easy-to-clean grinding area as well as openness for future extensions.

|

18.11.2016

|

|

|

COMBI plus 4-axis grinding machine

Featuring periphery, K-Lands and chip breaking grooves, the Agathon COMBI plus is designed to grind both sides of an indexable insert in one clamping. The universal field-proven machine concept of the earlier 350 COMBI has been continued with the new version, whilst the efficiency of the machine has been dramatically enhanced.

The 4-axis indexable insert grinding machine COMBI plus provides the user with maximum efficiency and reliability. A large range of inserts – from the very straightforward ISO-standard insert to the most demanding inserts (e.g. inserts for the manufacturing of crankshafts) – can be ground entirely in one single operation.

Complete machining is possible in automatic cycle through reclamping.

|

18.11.2016

|

|

|

Dom Plus 4-axis grinding center

High-precision 4-axis grinding center for the machining of indexable inserts on the periphery with two K-Lands through re-clamping

The Dom Plus is the direct successor of the proven Dom Semi. The 4-axis grinding center for machining periphery, clearance angles and two K-Lands stands for precision and process stability.

The Dom Plus is equipped with powerful, maintenance-free direct drives. A 180° rotating loading gripper provides increased flexibility in handling operations, such as when re-clamping workpieces to grind the 2nd chamfer.

The standard built-in pallet storage system with 4 drawers and space for 8 to 12 trays offers high production autonomy. The advanced machine control panel is the same as on the Leo Peri and Evo Combi machines.

|

18.11.2016

|

|

|

DOM Semi 4-axis grinding center

Highly precise 4-axis grinding center for the manufacturing of ISO-standard indexable inserts with periphery and one-sided K-Lands.

The machine, equipped with the latest control technology, combines the periphery grinding with K-Lands on one side and fully integrated linear handling as an economical grinding center.

The infeed axis is newly designed with a linear motor and a polymer concrete base dampens vibrations.

A fully protective enclosure and the primary protection of the grinding zone fulfill the high standards of CE conformity.

Fast setup and easy access for the operator to facilitate flexibility between small and large batches.

The proven Agathon's software with the well established syntax allows fast programming and the use of all existing programs of the 250, 350 and 400 generations.

|

18.11.2016

|

|

|

Leo Peri 4-axis grinding center

The latest and at the same time smallest grinding center for indexable inserts replaces the legendary 250 PA family which was launched forty years ago and which is still successfully being used at many production sites. The compact design of «Leo Peri» requires a footprint of less than 4 sqms accommodates a dynamic 4-axis machine suited for the machining of a wide range of materials. The new grinding center offers high user friendliness, excellent accessibility and grants short grinding times thanks to its rigid design. The «Leo Peri» comes equipped with the proven intuitive Agathon control technology which allows for the machine's easy and effortless operation. Due to the use of state-of-the-art direct drives, the machine is low on maintenance and extremely maintenance-friendly. The high machining and service quality provide for low production costs offering an optimized price/performance ratio.

|

18.11.2016

|