|

Company

Last Update: Oct 26, 2016

|

Machine

|

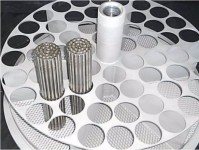

Spent fuel storage baskets

The spent fuel storage baskets are used to transfer the bundles with spent fuel from the primary storage tank and their dry storage inside the Spent Fuel Storage Facility (DICA). |

26.10.2016 |

|

The spent fuel storage pallets and pallets supports

The spent fuel storage pallets and pallets supports are used to support the bundles with spent fuel in the primary storage tank, with the purpose of wet storage for max. 10 years |

26.10.2016 |

|

Flow Assistant RAM Extension (FARE)

The Flow Assistant RAM Extension (FARE) is auxiliary equipment used to change the fuel in nuclear power plants. Its role is to facilitate the movement of the fuel bundle in the reactor’s channel when the speed of the coolant does not create the necessary hydraulic force. |

26.10.2016 |

|

The GRAPPLE Tool and the Sealing Plug

The GRAPPLE Tool and the Sealing Plug is a set of accessories used to discharge completely the fuel channels when a Fuelling Machine is not fully functional. |

26.10.2016 |

|

PRESS DATA (OTR BOM)

Single drive Access to maintenance of drive and lift cylinder Low operating height - segmented mold actuating cylinder inside of top link Stripping mechanism at rear of dome Crank gear with shrink fit throw trunnion |

26.10.2016 |

|

LT BAG-O-MATIC® Curing Press Data

Type: Twin-cavity platen with sectional mold capability Bladder Mechanism: Stand aid 3½" double acting center mechanism Loader: Uniformity 5000 Unloader: Deposit tires on customer supplied discharge conveyor |

26.10.2016 |

|

BAG-O-FORM Curing Press Data

Type: Twin-Cavity steam platen with sectional mold capability Bladder Mechanism: 3½" S.S. Center Mechanism Loader: ACCU-LOADER® precision with 6 shoes Unloader: Carry tires back, hold, and place on discharge system. |

26.10.2016 |

|

AUTOLOK® Curing Press Data

Twin-cavity platen all radial with both sectional mold and two- piece split mold capability, and prepared to accept SMO field kit BT System (Patent Pending) Individual, Swing-in style precision with 6 shoe contact (Patent Pending) Fork type unloader. Carries tires from the press to a cooling conveyor or station. Does not require exit conveyor. |

26.10.2016 |