|

Company

Last Update: Oct 22, 2016

|

Machine

|

Transfer presses

Ram slow motion can be link-drive or Servodrive, on the ground of the different applications and of the parts to be produced. On the ground of the table size and of the production needs, transfer presses can be made with two or four connecting rods Transfer presses usually have a large opening between the uprights to have the necessary space for the transfer system. |

22.10.2016 |

|

Presses for progressive tools

Presses can have fixed or variable stroke and the kinematic for ram movement can be eccentric, Esadrive, knuckle-joint, Link-drive or Servodrive, on the ground of the applications and the parts to be produced. |

22.10.2016 |

|

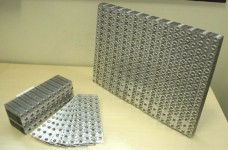

Fin die presses

The production of aluminium fins for radiators requires extremely accurate and reliable machines capable to work at high speed with very thin material (aluminium or copper ≤0,2 mm), in order to assure the necessary constant precision required by this specific type of product. |

22.10.2016 |

|

Roll forming lines

Balconi manufactures and supplies roll forming lines for band width from 15 to 500 mm and thickness from 0,6 to 3 mm |

22.10.2016 |

|

quick -tool change systems

Brackets with rollers or ball ways in the press bolster |

22.10.2016 |

|

shears

In order to shear the band safely and quickly, Balconi manufactures and supplies hydraulic shears that are installed between the press uprights at the entry side. |

22.10.2016 |

|

feeding lines

Balconi manufactures his own feeding lines for band width from 1000 mm to 2000 mm. These feeding lines are fully integrated in the press PLC and this this allows time saving during production change. |

22.10.2016 |

|

electronic feeders

Balconi manufactures his own electronic feeders for band width from 200 to 2000 mm Feeders are fully integrated in the press PLC and this allows time saving during production change. |

22.10.2016 |