|

Company

Last Update: Oct 22, 2016

|

Machine

|

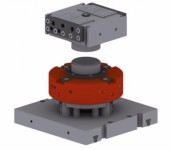

PM 2500 Sub-press devices

Sub-press with movable die holder . Vertical forging, one or two pieces. |

22.10.2016 |

|

FPM ES 150 Friction screw presses

Special casting material Hydraulic pre-load of frame with two steel tie rods Main screw in special forged steel. Bushing in special bronze alloy. Disk shaft in forged steel. |

22.10.2016 |

|

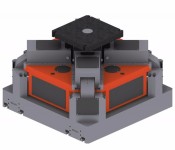

APS 4000 Sub-press devices

Sub press “bell” with 4 orthogonal movable sectors max. stroke 140 mm.

Automatic lubrication.

Bell external diameter 760 mm.

Semi candle incorporated into the base.

Stroke of the front dieholder sector 250 mm.

Stroke of the pinholder sector 130 mm.

Pneumatic opening and lockup of the front dieholder sector and pinholder sector.

Back dieholder stroke 400 mm.

Pneumatic opening and lockup of the back dieholder sector.

Automatic ejection of the piece down from above.

|

22.10.2016 |

|

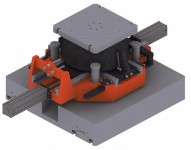

AP4-4000 Sub-press devices

Drilling sub press with N°4 orthogonal carriages, driven by N°4 columns, max. stroke 110 mm.

Automatic lubrication.

Semi candle incorporated into the base.

Width of the lever 160 mm.

Diameter of the lever pin 160 mm.

Radius of the lever 290 mm.

Max. dimension drilling pin 100 mm.

Ejection from the top, with ram ejection bar

Ejection stroke 30 mm.

Max. dies dimension 290x290 h 90.

|

22.10.2016 |

|

FPM E-UARM 4000 Unloading arm

TECHNICAL DATA slide stroke:nd mm load capacity:4 kg vertical stroke:nd mm electrical components:Siemens handling type:Meccanica conditions:New |

22.10.2016 |

|

FPM E-ARM 4000 Loading arms

ELECTRONIC LOADING ARM For horizontal and vertical loading of the billet with brushless motor at programmable axis and press interpolation with electric axis. |

22.10.2016 |

|

FPM EP 360 Friction screw presses

Special casting material Hydraulic pre-load of frame with two steel tie rods Main screw in special forged steel. Bushing in special bronze alloy. Disk shaft in forged steel. |

22.10.2016 |

|

Friction screw presses_FPM ES 130

Special casting material Hydraulic pre-load of frame with two steel tie rods Main screw in special forged steel. Bushing in special bronze alloy. Disk shaft in forged steel. |

22.10.2016 |