|

Company

Last Update: Sep 7, 2016

|

Name

|

Danieli & C. Officine Meccaniche S.p.A.

|

|

Responsible

|

Scordi Andrea - Director Sales

|

|

Locations

|

Egypt

,

Brazil

,

Mexico

,

China

,

India

,

South Korea

,

Thailand

,

Vietnam

,

Denmark

,

France

,

Italy

,

Portugal

,

UK

,

Russia

,

Ukraine

,

USA

|

|

Email

|

danieliofficinemeccanichespa@legalmail.it

|

|

Phone

|

+(39) 0432.1958111

|

|

Website

|

http://www.danieli.com/en/contacts/management.htm

|

|

Description

|

An international, multicultural team covers the full spectrum of technology, from iron ore to the different finished products. After years of proven success, we have confirmed our position as the world leader for minimills and long products rolling mills, and the most recent achievements in flat products and the final acquisition of Danieli Corus in Ijmuiden (Holland) have solidified Danieli's position in the field of the full integrated plants.

With our original mottos - “Danieli the reliable and innovative partner in the metal industry” and “we do not shop around for noble equipment”, - we have added now “Danieli a step ahead”, which expresses our determination to improve our current performances. To do this, we launched a program called “Metamorphosis 2”: innovation to our operating methods/patterns and consequently to our organization in order to enhance the technical and economic competitiveness, speed, quality, customer service. Further to accomplish this, our managers are taking regular courses, to gain the skills necessary to deal with the demands of today’s world. Also our motto - “A step ahead in Capex and Opex”, expresses our desire to transfer the same concepts to our partner customers.

|

|

|

|

|

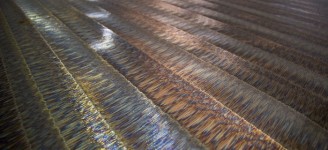

Hot Rolling Mills

Danieli metals technology for lowest Capex and Opex.

|

15.08.2016

|

|

|

Cold Rolling Mills

The highest flatness strip production for metal industry.

|

15.08.2016

|

|

|

Aluminium Foil Rolling mills

Danieli FATA Hunter built the first foil rolling mill in 1961. Today, the company’s reference list includes 101 Foil Rolling Mills all over the world. Each mill has the variables in size, speed, coil and core handling, gauge control, pass line configuration, and computerized accessories to meet any specification and – more important – any expectation. The Danieli FATA Hunter foil rolling mills are designed and engineered incorporating the technology and operating practices available from the vast experience of supplied mills in operation worldwide.

|

15.08.2016

|

|

|

Aluminium Plate Stretchers

Danieli sheet and plate stretchers are used to improve flatness and minimize residual stresses to produce the highest quality aluminium alloy plates. The Danieli Stretcher is fully hydraulic and uses a Danieli Automation process control system, together with state-of-theart hydraulic components. The Danieli machines are equipped with visual systems, for reliable plate loading, and with Danieli Operator Assistant system to support the operator in presetting the transversal press. Built-in features also include reliable clamping capability, shock prevention and elongation control.

|

15.08.2016

|

|

|

Alcoa Micromill technology by Danieli

The Alcoa Micromill™ technology by Danieli produces the most advanced aluminium sheet on the market. The Micromill process dramatically changes the microstructure of the metal,producing an aluminium alloy that has 40-percent greater formability and 30-percent greater strength than the incumbent

automotive aluminium used today, while meeting stringent automotive surface quality requirements.

|

15.08.2016

|

|

|

Aluminium DiamondFlex Mills

Best quality at the lowest cost.

|

15.08.2016

|

|

|

Aluminium Hot Rolling Mills

Superior flexibility with high-quality production and maximum material yield.

|

15.08.2016

|

|

|

Forging press

Two / Four-column forging press.

|

15.08.2016

|

|

|

Bar Drawing Plants

Drawing is the process used to improve the dimensional tolerance of hot rolled coil or bar, by means of cold deformation. Danieli supplies both coil to bar drawing plants for calibration of wire diameters 4.5 - 45 mm as well as bar to bar drawing plants for calibration on bar diameters up to 150 mm.

|

15.08.2016

|

|

|

H³ - Wire Rod Mills/Bar-in-coil

Cutting-edge Process and Technology for Superior Quality Wire Rod/Bar-in-coil Manufacturing.

|

15.08.2016

|

|

|

SQS - Medium & Heavy Section Mills

Danieli can offer different section mills solutions that can be split in three main categories, light, medium and heavy section mills, according to the flange height of the beams.

|

15.08.2016

|

|

|

SQB - Big Bar Mills

Large rolled bars are used in all cases where the mechanical, metallurgical and dimensional properties of products coming directly from the conticaster are inadequate to fulfil applications in automotive industry, oil and gas, wind farms, mechanical and metalworking fabrication.

|

15.08.2016

|

|

|

Billet and Bloom Grinders

Top Technology and Quality in inspection and grinding of Long Products.

|

15.08.2016

|

|

|

Cold Mill Complex

Danieli experience to optimize production routes.

|

15.08.2016

|

|

|

Plate Mills

Customized solutions for better product quality and higher operational efficiency in plate production.

|

15.08.2016

|

|

|

Steckel Mills

A unique combination of low capital cost and product flexibility.

|

15.08.2016

|

|

|

Hot Strip Mills

High-tech rolling mills ensuring the most user-friendly operation and lowest maintenance in order to achieve the closest finished product tolerances.

|

15.08.2016

|

|

|

Slab Grinders

The most advanced and efficient method for conditioning surfaces of carbon and stainless steel slabs.

|

15.08.2016

|

|

|

Shredder Plants

The most modern and cost-effective solutions for shredding and recycling scrap metals and non-ferrous materials.

|

15.08.2016

|

|

|

Hot Blast Stoves

Danieli Corus hot blast stoves have a proven service life of over 30 years, surpassing the lifetime capability of most blast furnace designs. This makes selection of this hot blast stove technology a once-in-a-lifetime decision.

|

15.08.2016

|

|

|

Scrap shears

With their sturdy design and high compacting ability, our scrap shears are ideal for processing metal scrap, where high densification and productivity are required.

|

15.08.2016

|