|

|

Horizontal milling and boring machines > MAXIMA

machine design is based on design groups of WRD machines, which are arranged in a cross - bed design

power machining of extremely heavy and large workpieces from several sides

machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

either HEIDENHAIN iTNC 350, SINUMERIK 840 or FANUC control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WHR 13 (Q)

The horizontal boring and milling machine with traveling ram and the working spindle type WHR / WRD 13 (Q) is based on the original generation of CNC horizontal milling and boring machines WHN (Q)13 CNC of TOS VARNSDORF a.s

WHR 13 (Q) is horizontal boring and milling machine which are offered with spindle diameter 130 mm.

The machines are continuously controlled in five axes (X - base cross travelling, Y - headstock vertical adjustment, V - RAM longitudinal travel, Z longitudinal travel of the column and W - working spindle longitudinal travel).

machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

HEIDENHAIN iTNC 530 HSCI, Sinumerik 840 D-SL or FANUC 30i/31i control system can be selected for controlling the machine.

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WHN(Q) 13-15 CNC

the most successful machine produced by TOS VARNSDORF a. s. (more than 2,000 produced machines)

universal machine tool for precise milling, coordinate boring, the boring and cutting of box and plate plate screws and comlicated workpieces with weight of up to 25,000 kg

machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WHN 130 (Q, MC)

leading edge technology machine corresponding with the needs of the up-to-date progressive machining

effective universal chip removal machining of non-rotary workpieces of larger size and weight, employing the partprograms of the most progressive technological features

modular design offers a chance to choose from a broad range of optional travel tenghts in all axes. This provides the customers with a possibility to choose for themselves a machine that suits their needs the most

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WHN 110 (Q, MC)

eading edge technology machine corresponding with the needs of the up-to-date progressive machining

effective universal chip removal machining of non-rotary workpieces of larger size and weight, employing the partprograms of the most progressive technological features

modular design offers a chance to choose from a broad range of optional travel tenghts in all axes. This provides the customers with a possibility to choose for themselves a machine that suits their needs the most

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

on the customer’s wish the machine can be supplied also in design „BASIC“ with modified technical parameters

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WH(Q) 105 CNC

it is suitable for the most demanding applications

high cutting performance and outstanding product reliability make this machine ideal for one-off applications or volume production in the most difficult operations

it is intended for broadly universal chip removal machining of non-rotational parts of smaller size and weight particularly of cast iron, cast steel and steel, employing the most sophisticated part-programs

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Horizontal milling and boring machines > WH 10 CNC

the smallest type representative of the original line of the CNC horizontal boring machines of TOS VARNSDORF a. s. which was designed during the modernisation of WHN 9 A/B

technologically and price-wise is it a perfect machine for tool shops and plants with medium batch production

it is suitable for series production and high technologies

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Floor type horizontal boring mills > WRD 180 H

WRD 180 H hydrostatic floor-type horizontal boring and milling machines are designed to serve for precise coordinate drilling, boring, milling, and thread cutting.

They are particularly suitable for the machining of box-, plate- and complex-shape work pieces made of cast iron, cast steel, steel or other materials machinable with cutting tools, and for large and very large size and weighty components.

The machines are well usable for batch production and complex process applications.

Machine are offered with three type of working spindel diameter (160, 180 and 200)

The machines are continuously controlled in four axes (X - base cross travelling, Y - headstock vertical adjustment, Z - sliding block longitudinal travel and W - working spindle longitudinal travel).

They can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value.

HEIDENHAIN iTNC 530 HSCI, Sinumerik 840 D-SL or FANUC 30i/31i control system can be selected for controlling the machine.

|

13.07.2016

|

|

|

Floor type horizontal boring mills > WRD 170 (Q)

the biggest type of floor type horizontal boring machines manufactured by TOS VARNSDORF a.s.

intented for precision and high-efficient coordinate boring, drilling, milling and thread-cutting particularly in the case of large-scale, heavy and structurally difficult work-pieces made of cast iron, cast steel and steel

according to process needs, the machine can be extended with a clamping field consisting of clamping plates or with one or more additional tables

machines can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

on the customer’s wish the machine can be supplied also in design with spindle diameter of 160 mm

|

13.07.2016

|

|

|

Floor type horizontal boring mills > WRD 130/150 (Q)

twin-type of machines of the same concept and frame, but different main motor outputs, different headstocks and spindle speeds

intented for precision and high-efficient coordinate boring, drilling, milling and thread-cutting particularly in the case of large-scale, heavy and structurally difficult work-pieces made of cast iron, cast steel and steel

according to process needs, the machine can be extended with a clamping field consisting of clamping plates or with one or more additional tables

machines can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

either SINUMERIK 840D, HEIDENHAIN iTNC 530 or FANUC 31i control system can be selected for controlling the machine

on the customer’s wish the WRD 150 type can be supplied also in design with spindle diameter of 160 mm

|

13.07.2016

|

|

|

Floor type horizontal boring mills > WRD 13 (Q)

The horizontal boring and milling machine with traveling ram and the working spindle type WHR / WRD 13 (Q) is based on the original generation of CNC horizontal milling and boring machines WHN (Q)13 CNC of TOS VARNSDORF a.s

WRD 13 (Q) is horizontal boring and milling machine which are offered with spindle diameter 130 mm.

The machines are continuously controlled in four axes (X - base cross travelling, Y - headstock vertical adjustment, Z - sliding block longitudinal travel and W - working spindle longitudinal travel).

machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

HEIDENHAIN iTNC 530 HSCI, Sinumerik 840 D-SL or FANUC 30i/31i control system can be selected for controlling the machine.

|

13.07.2016

|

|

|

Floor type horizontal boring mills > GRATA

the newest product of floor type horizontal boring mills of TOS VARNSDORF a.s.

machine for precise coordinate milling, drilling and thread cutting which is particularly suitable for the machining of box-, plate- and complex- shape workpieces made of cast iron, cast steel, steel or other materials, and for large and weighty components

machine can be extended with a wide selection of technological accessories that significantly widen the machine technological utility value

either SINUMERIK 840D or HEIDENHAIN iTNC 530 control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Machining centres > WHtec 130

WHtec 130 Machining Center is the biggest type representative of the most recent series of machining centers comprehensively called WHtec from production of TOS VARNSDORF a.s.

fully enclosed machining centre with bed arrangement into shape T with horizontal spindle axis and rotary table

according to technological needs the machines can be extended with modules of automatic tool change and automatic pallet change

universal and special technologies of cutting operation incl. the most advanced technologies of five-axes and HSC machining

either SINUMERIK 840D or HEIDENHAIN iTNC 530 control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Machining centres > OPTIMA

fully enclosed machining centre with bed arrangement into shape T with horizontal spindle axis and rotary tableghg

according to technological needs the machines can be extended with modules of automatic tool change and automatic pallet change

universal and special technologies of cutting operation incl. the most advanced technologies of five-axes and HSC machining

either SINUMERIK 840D or HEIDENHAIN iTNC 530 control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Machining centres > PRIMA

fully enclosed machining centre with bed arrangement into shape T with horizontal spindle axis and rotary table

according to technological needs the machines can be extended with modules of automatic tool change and automatic pallet change

universal and special technologies of cutting operation incl. the most advanced technologies of five-axes and HSC machining

either SINUMERIK 840D or HEIDENHAIN iTNC 530 control system can be selected for controlling the machine

|

13.07.2016

|

|

|

Special machines > SPEEDtec

high productive machine tool centre for high speed machining of cabinet, plate and dimensional difficult workpieces with maximal weight of 4000 kg

suitable for series production and demanding technological usage

possibility of permanent machining of workpieces with help of two independent spindles from booth sides - saving of machining time up to more than 50%

machine is equipped by automatic tool change (tool change time - 6 sec) and also by automatic pallet change

complete covering ensures the conformity with strict ecological and safety requirements

|

13.07.2016

|

|

|

Special machines > WRD 150 DUO

the workplace is making by two independent WRD 150 Q machines

both machines have common workspace created by the S30 rotary table and by floor plate

main advantage of this solution is the possibility of permanent machining of workpiece with help of two independent spindles or machining of two different workpieces

the machines could be directly controlled from operator platform situated separately on every machine, or from control station common for both maschines

|

13.07.2016

|

|

|

Special machines > Technologies

Special machines > Technologies

|

13.07.2016

|

|

|

HPR 50 - vertical manual milling head

manually, semi-automatically or automatically fastening on the machine

manually positioning and clamping

manually or semi-automatically clamping of tools

3,000 R.P.M. / 25 kW / 1,200 Nm

|

13.07.2016

|

|

|

HUR 50 - universal milling head, manually adjustable

manually, semi-automatically or automatically fastening on the machine

manually positioning and clamping

manually clamping of tools

3,000 R.P.M. / 20 kW / 1,000 Nm

|

13.07.2016

|

|

|

HUI 50 - universal milling head, automatically adjustable

automatically fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

3,000 R.P.M. / 32 kW / 1,000 Nm

|

13.07.2016

|

|

|

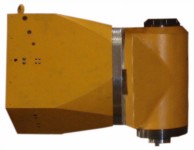

HPI 50 - 1-axes vertical milling head automatically indexed

semi-automatically or automatically fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

4,000 R.P.M. / 37 kW / 1,200 Nm

|

13.07.2016

|

|

|

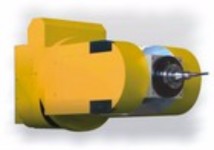

HPIT 50 - 1-axes heavy vertical milling head automatically indexed

semi-automatically or automatically fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tool

2,500 R.P.M. / 70 kW / 2,500 Nm

|

13.07.2016

|

|

|

HOI 50 - orthogonal milling head

automatically or permanent fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

4,000 R.P.M. / 37 kW / 1,200 Nm

|

13.07.2016

|

|

|

HOF 50 - orthogonal milling head continuously positioned (0,001°)

automatically or permanent fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

in the development, delivery during the year 2013

4,000 R.P.M. / 37 kW / 1,200 Nm

|

13.07.2016

|

|

|

HV/V - fork type milling head driven by the spindle

automatically fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

3,500 R.P.M. / 22 kW / 500 Nm

|

13.07.2016

|

|

|

HV/E-H - fork type milling head with electrospindle

automatically or permanent fastening on the machine

automatically positioning and clamping

manually or automatically clamping of tools

20,000 R.P.M. / 43 kW / 120 Nm

|

13.07.2016

|

|

|

Accessories > Milling attachment

FP 40-10 (FP 50-13) - vertical milling head

accessories for the WH 10 CNC and WHN(Q) 13 CNC machines

milling operations of vertical and inclined surfaces

manually fastening on the machine, manually clamping of tools

900 (600) R.P.M. / 10 (20) kW / 250 (1,000) Nm

UFP 40-10 (UFP 50-13) - universal milling head

accessories for the WH 10 CNC and WHN(Q) 13 CNC machines

milling operations of different inclined surfaces parallel to any of the principle axes of the machine

manually fastening on the machine, manually clamping of tools

900 (600) R.P.M. / 10 (20) kW / 250 (1,000) Nm

|

13.07.2016

|

|

|

Accessories > Facing heads

LD 650 - facing head

facing and outside turning or boring of cylindrical, conical and otherwise shaped surfaces of large diameters

manually or automatically fastening on the machine

automatically control of the slide position

Facing head dia mm 650

Slide travel U mm 170

Max. speed R.P.M. 200

Max. torque Nm up to 3 322

Total weight kg 200

|

13.07.2016

|

|

|

Accessories > Add-on tables

S 5 - S 50

workpiece clamping and positioning in the technological workplaces

they may be multi-applied

control and positioning is integrated in CNC control system

|

13.07.2016

|

|

|

Accessories > Clamping equipment

UD - CLAMPING PLATES

optional accessories for the floor type horizontal boring mills

UK 500, UK 1000, UK 2000, UK 2500 - CLAMPING CUBES

UU 800 - UU 6000 - CLAMPING ANGLE PLATES

|

13.07.2016

|

|

|

Cooling equipment

CHOV - cooling through the spindle

Basic specifications

Horizontal milling and boring machines

Cooling input: inside nozzles

Collecting tank capacity dm3 900 900

Coolant pump motor power kW 2,2 2,2

Coolant pump rated pressure MPa 0,4 - 1(2) 0,3

Pump output (supplied volume) 1/min 30 50

Floor type horizontal boring mills

Cooling input: inside nozzles

Collecting tank capacity dm3 900 900

Coolant pump motor power kW 4 2,2

Coolant pump rated pressure MPa 1,38/2,58 0,43

Pump output (supplied volume) 1/min 30 60

Machining centres - TOStec

Cooling input: inside nozzles

Collecting tank capacity dm3 900 900

Coolant pump motor power kW 2,2 (4, 4, 8) 2,2

Coolant pump rated pressure MPa 1 (2, 3, 4) 0,3

Pump output (supplied volume) 1/min 30 50

CHZ - outside cooling through the nozzles

Basic specifications

Horizontal milling and boring machines (CHZ 13/15)

Collecting tank capacity dm3 200

Coolant pump motor power kW 0,8

Coolant pump rated pressure MPa 0,3

Pump output (supplied volume) 1/min 32

Floor type horizontal boring mills (CHZ 130-150)

Collecting tank capacity dm3 900

Coolant pump motor power kW 2,2

Coolant pump rated pressure MPa 0,43

Pump output (supplied volume) 1/min 60

Machining centres - TOStec

Collecting tank capacity dm3 900

Coolant pump motor power kW 2,2

Coolant pump rated pressure MPa 0,3

Pump output (supplied volume) 1/min 50

|

13.07.2016

|

|

|

SZP - optional fixture support

it improves significantly the putting off the optional accessories determined for the automatic control of the PICK UP change

number of places in a magazine: 1 - 4

tilting or roll-up doors

possibility of delivery of special auxiliary rack placed on the working rotary table

Chip conveyor

together with transport is possible to separate cooling liquid

it is possible to keep it or to transport it back into machine system

Spindle guiding support - short, long

it ensures a significant increase in the rigidity of the work spindle

ii is recommended for power machining or also for precise machining with the spindle traveled out to a greater extent

Workpiece and tool probes

measuring probes supplied by leading specialized companies HEIDENHAIN, RENISHAW etc.

|

13.07.2016

|

|

|

Standard accessories

List of standard equipment:

Anchoring hardware kit

Pull studs for tool clamping

- 30 pcs for design without ATC

- for ATC design - according number of tools in magazine

Spindle taper brush

Set of service and maintenance tools

Set of consumable parts kit

Accompanying technical documentation including operating manual

Spindle guiding support - short PVK 10-170 WH 10 CNC

Spindle guiding support - short PVK 105-250 WH(Q) 105 CNC

Spindle guiding support - short PVK 112 WHN 110(Q, MC)

Spindle guiding support - short PVK 130 WHN 130(Q, MC)

Spindle guiding support - short PVK 13-300 WHN(Q) 13 CNC

Spindle guiding support - short PVK 100 PRIMA

Spindle guiding support - short PVK 112 OPTIMA

Spindle guiding support - short PVK 130 VARIA

|

13.07.2016

|